Reduced to one connector family, aligned cable lengths

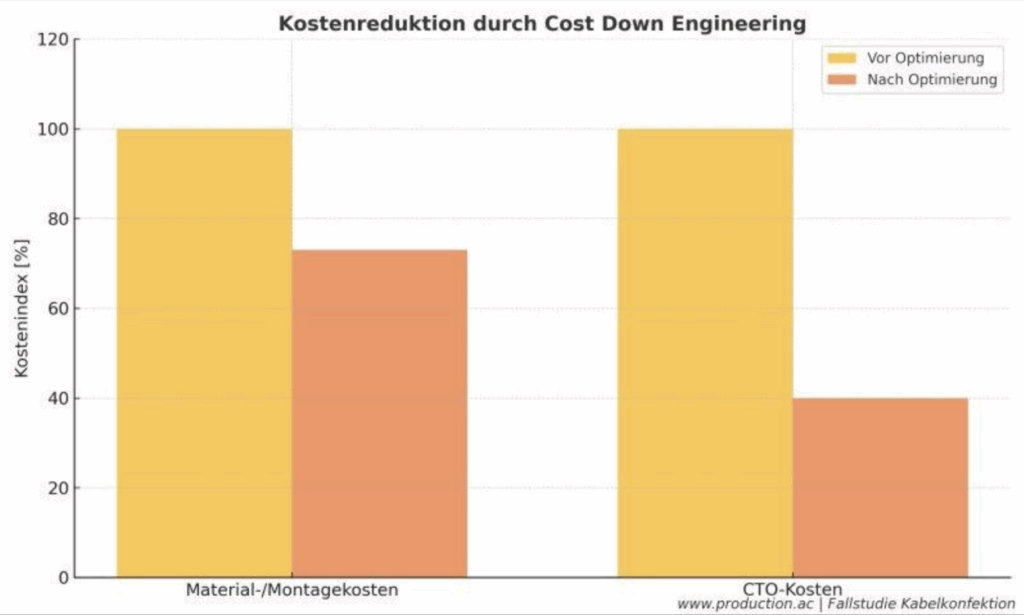

Reduced assembly time by 34%

Combined two cable sets into one

Moved to Eastern European facility (previously manual final assembly in Germany)

Cost down engineering isn’t forced cost cutting—but systematic reassessment of established practice. Those who rethink value creation create room for margin—and maintain competitiveness.

Eine gemeinsame Veranstaltung von Mikrocentrum High Tech Platform und der DNHK