We understand the challenges of the automotive sector—and deliver precise, scalable solutions for your production.

The automotive industry is undergoing profound change. Electromobility, autonomous systems, and new mobility concepts are transforming requirements for production and supply chains. At the same time, expectations for time-to-market, quality, and sustainability are rising. Anyone who wants to remain competitive today needs agile partners with deep industry understanding.

production.ac supports automotive customers with tailor-made production solutions—from prototype manufacturing to series readiness. Our expertise in the precise machining of complex assemblies, combined with digital process integration, ensures efficiency, traceability, and maximum quality. In this way, we help you shorten innovation cycles and reliably meet standards

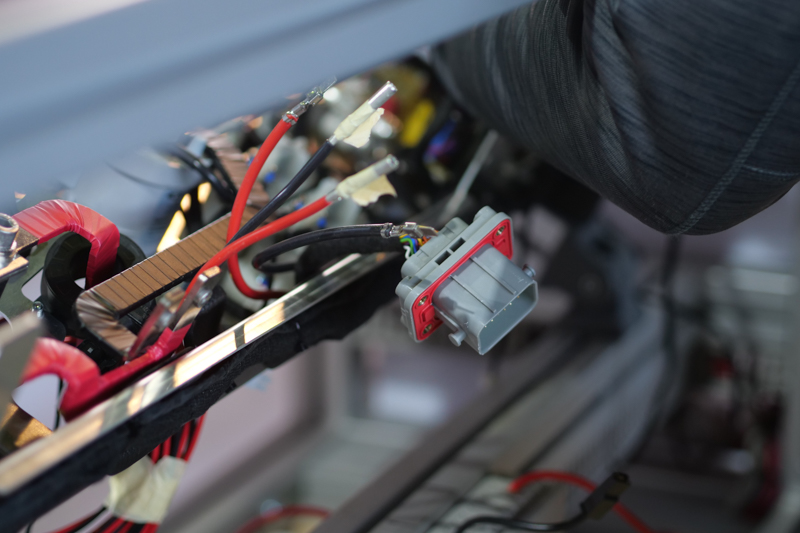

We realize projects such as HV assemblies for charging units, complex housings for control devices, or precision components for driver assistance systems. Our solutions are tailored to the high demands of the automotive industry—robust, compliant with standards, and scalable.

Our processes are certified according to ISO 9001 and IATF 16949. We rely on comprehensive testing procedures, digital traceability, and continuous process optimization. This guarantees consistently high quality—even for complex requirements and high quantities.

Short response times, deep technical know-how, and a high degree of flexibility make us the ideal partner for automotive projects. We think ahead, act quickly, and deliver reliably—even under tight timeframes and demanding specifications.

Planning a new project in the automotive sector? Let’s develop the right solution together—precise, fast, and reliable.

For a leading Tier-1 supplier, we developed and brought into series production an HV assembly for a charging unit. The challenge: high thermal resilience within minimal installation space. Through close collaboration with the customer and precise manufacturing, we were able not only to meet but exceed the requirements—while simultaneously reducing production costs.

+49 152 22186226

kaspers@production.ac

Nerscheider Weg 170

52076 Aachen

+49 2408 9377736

sales@production.ac