Consistent use of fully shielded, IP67-certified circular connectors in design

Actual location: protected indoor area inside a control cabinet

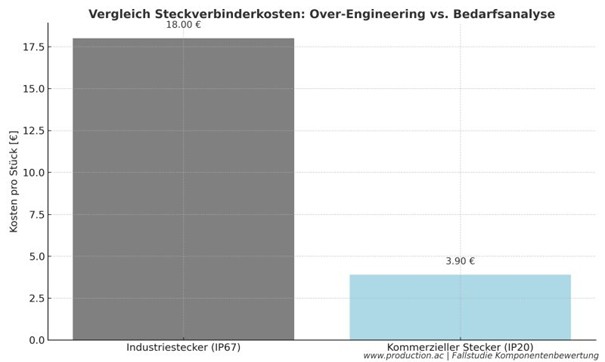

Price per connector: >€18, though only IP20 was needed

The design decision was made years ago for “safety” reasons—but never questioned since

IP67 and shielding not needed in this application

Functionally equivalent for €3.90 instead of €18.00

Standardised part numbers + new reference design

Technical requirement ≠ wish list solution

Overpriced parts are rarely a technical problem—they’re usually due to a lack of economic evaluation in design. Cost down engineering also means: back to reason—and away from “over-engineering”.