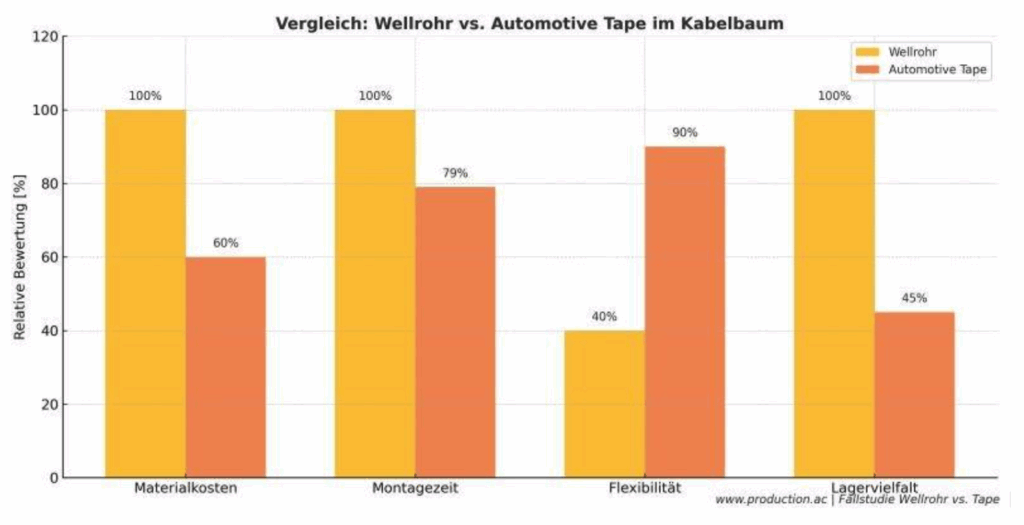

An OEM for mobile working machines consistently used corrugated tubing for mechanical protection in all cable sets—even in areas where this was not technically necessary, based on old design guidelines.

Identified non-critical areas

Tape met all safety classes up to 105 °C, abrasion resistant, OEM-approved

Replaced by winding tape or flex tape

Much quicker processing possible

Not every form of protection makes sense—some measures are simply a matter of habit. A sober assessment of actual stresses can drastically reduce material, time, and effort. Cable protection doesn’t need to be maximal—just suitable.