With Cost-Down Engineering, we reduce your production costs in a targeted manner—without compromising on quality or functionality.

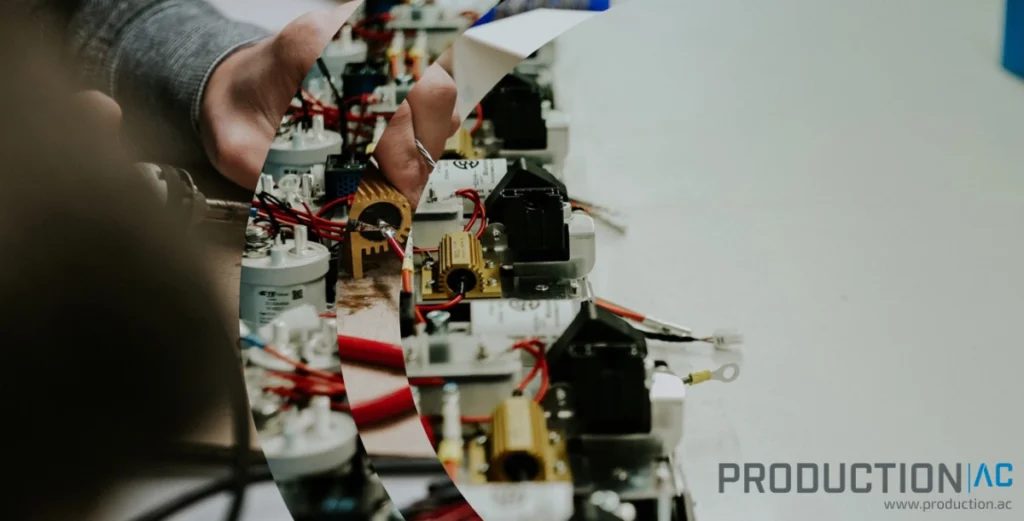

Cost-Down Engineering is a strategic approach to reducing product and process costs. By conducting targeted analyses and optimisations in manufacturing—such as AC production lines, high and low voltage wiring harnesses, and PDU systems—we increase efficiency whilst safeguarding product quality.

With Production AC, companies receive reliable solutions for power distribution that meet the highest requirements for efficiency and customised adaptation—enabling targeted cost reduction.

Identifying and eliminating unnecessary expenses

Optimisation without loss of quality

Clear project phases and measurable results

Use of modern analysis and production tools

Tailored solutions for automotive and industrial sectors

From development and prototype construction to series production – our international network enables project-oriented delivery and assembly worldwide.

Our technological solutions represent intelligent cost reduction across the entire process chain—from procurement of components to end-of-line testing. Particular emphasis is placed on digital analysis methods, lean manufacturing processes, and flexible design strategies for wiring harness and PDU production.

CNC-controlled crimping technology

This automated solution enables significant savings through optimized material utilization and the highest connection quality.

Automated EOL test benches

The 100% verification of electronic functions enables early fault detection and reduces rework costs.

EMC-optimized housing designs

Minimize interference and avoid costly rework – ensuring efficient and stable production.

Thermally engineered designs

Ensure cost-effective cooling and long service life through targeted material selection and optimized construction.

Modular architecture

Allows rapid adjustments and reduces development costs, as changing requirements can be covered flexibly.

Our expertise enables us to implement both series solutions and custom special designs efficiently and in compliance with standards.

Production AC Power Distribution Units offer industry solutions consistently focused on cost optimisation and process simplification—for example in mechanical engineering, industrial electronics, electrical engineering, and energy distribution.

The project process for Cost-Down Engineering is clearly structured: from on-site analysis to targeted identification of cost-saving opportunities, development of optimisation solutions, implementation, and monitoring—all accompanied by intensive customer communication. This ensures efficiency, compliance, and punctuality.

Begin your Cost-Down project with us—efficiently, transparently, and measurably. Contact us for a first consultation directly at your site.

Depending on the project and industry, savings of 10–30% are possible.

Yes—only by doing so can we realistically assess processes and implement targeted optimisation.

Absolutely. Especially with serial products, major savings can be achieved through redesigns and process optimisation.

Mainly electrical engineering, commercial vehicles, energy technology, off-highway vehicles, rail, and maritime.

+49 152 22186226

kaspers@production.ac

Nerscheider Weg 170

52076 Aachen

+49 2408 9377736

sales@production.ac